Description

System for the automation of industrial sliding doors or folding gates of any size, weight or number of leaves. Result of an important technical evolution due to many applications within special project, the complete system MR300L developed by CASIT is today the most reliable and comprehensive solution ever for the automation of:

- folding doors with even or odd number of leaves with unilateral or bilateral manual control (with provision for subsequent automation) or motorized sliding

- doors with even or odd number of leaves with unilateral or bilateral manual control (with provision for subsequent automation), or the motor control

Benefits and features of the system

Minimum size and maximum capacity flow

Support rail with exclusive design, only 130 mm in height, consisting of steel profiles with very high yield strength and rounded, for a better distribution of the load and a reduction of wear.

Trolleys are also rounded and designed to evenly distribute the load.

Slotted mounting brackets and adjustable for easy installation.

Special shelves options allow for vertical and horizontal adjustment of the guide (see OPTIONAL››)

Modularity

The guide is produced in modules standard 2.5 or 3 meters, connected together via a system of bolted brackets. If required modules can be welded together.

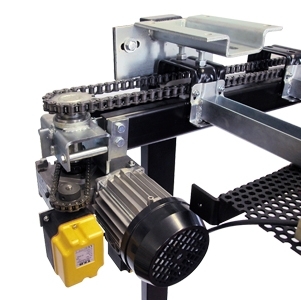

Motorization compact and for intensive use

The 2 ends of the guide are prepared for fixing (bolt-through plates), the motor and pinion with the function of reference and chain tensioner (designed to mount left or right end of the guide).

The gearmotor is designed specifically for CASIT from intensive industrial doors, sized to not spill over beyond the height of the guide. It consists in a fan-cooled motor, single or three phase and the worm gear CASIT, irreversible closing of the door to ensure security against burglary.

Stopping the engine is controlled by electromechanical limit switches on board motor.

A release device, integrated in the gearbox, controlled by a wire rope and the flexible tube, operated from below by a turning handle allows manual control by pushing the door. The handle has a security key.

Noiseless and smooth transmission

The drive chain runs on the horizontal axis and it is supported throughout its length by the slides easy replaceable.

The connector chain on the main cart (gear drive) is built so as to be oriented either to the right or left (in the rails with one only motorized engine, but with bilateral opening, the two connectors chain are the same, but oriented like mirror image). In the case of folding gates, the connector chain on the main cart and the cart itself (offset pin type) are specially shaped to bring, in closing, as much as possible the first leaf to the door jamb stop (unilateral opening) or to the opposite leaf

(both sides opening).

Lower rail section

The lower guide plate is made of galvanized steel and it is shaped in order to optimize the strength and locking into the ground.

Top rail section

Each installation requires a different type of guide, designed to improve the performance of the automation.

SLIDING DOORS LATERALLY ON THE SIDE (1 OR 2 RIGID LEAVES):

Gear motors, chain and trolleys have the same features of the folding doors, but driving suspension is double the width of the doors.

On (removed the) demand and after technical evaluation, we provide different versions for industrial telescopic sliding doors:

– with 2-3 leaves for unilateral doors opening

– with 4-6 leaves for bilateral doors opening

FOLDING DOORS WITH REDUCED LATERAL SPACES:

the proposed solution perfectly solves this problem of installation, but requires a larger footprint in terms of height and additional cost depending on the technical solutions adopted.

INDUSTRIAL SLIDING FOLDING DOORS, MANUALLY PUSH:

The adopted system for the upper guides allows an excellent handling even in the presence of industrial doors of large dimensions and weight; in addition to a predisposition for a future automation and motorization system. Carts suspension and diverter rollers are identical at the automated solution to ensure smoothness and durability.